Rigsight — Real-Time Telemetry for SFX Rigs

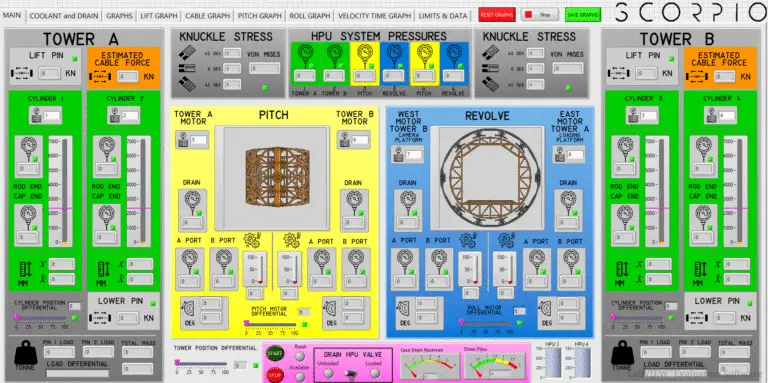

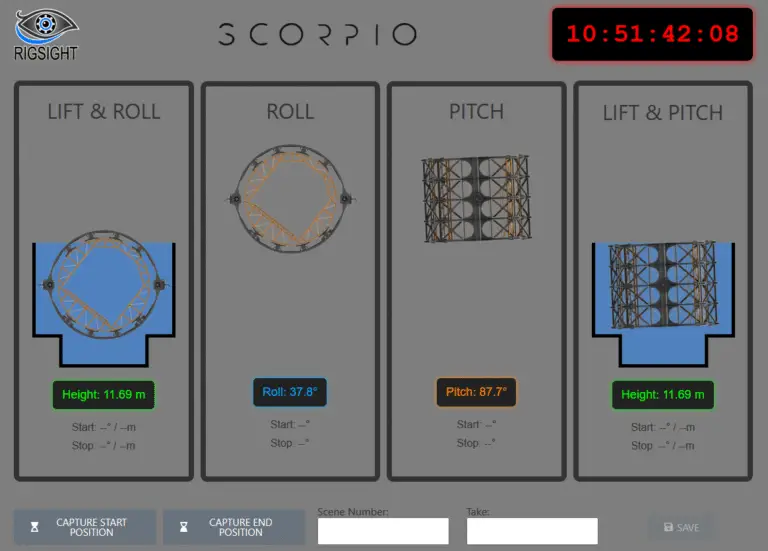

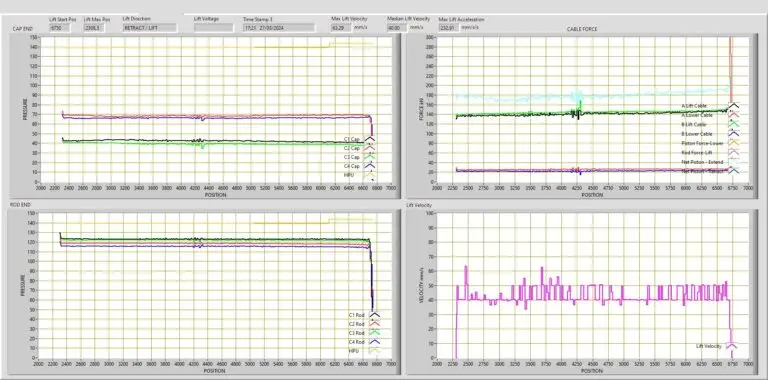

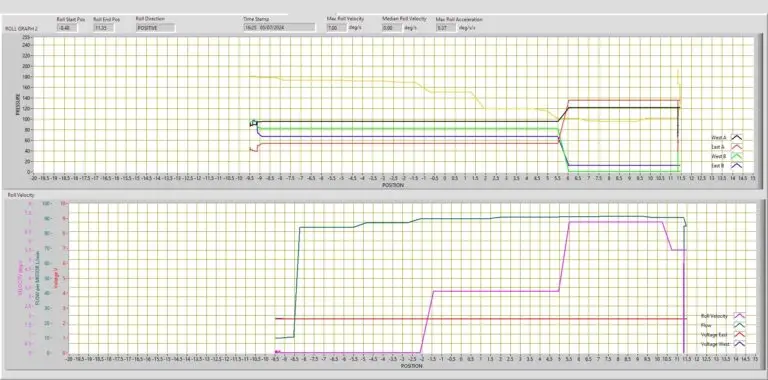

Rigsight is a custom telemetry system for special-effects rigs. It collects live position, pressure, and load data to monitor SFX performance, document tests, prove compliance, and reduce risk—helping productions make faster, better decisions on set.

What Rigsight Tracks

Position / displacement (linear or rotational)

Pressures (hydraulic / pneumatic)

Loads / forces / stresses (tension, compression, lifting)

Velocity / rate and cycle counts

System status & limits (end-stops, interlocks, E-stop events)

Timestamps for test runs and on-set takes

Why It Matters

Safety & compliance: Evidence-based sign-off with recorded datasets.

Speed on set: Real-time dashboards streamline decision making.

Repeatability: Hit the same cue and motion profile every time.

Proof for production: Exportable reports for H&S, insurers, and clients.

Optimisation: Diagnose performance, spot drift, and fine-tune rigs.

How It Works

Sensors selected for the rig (load cells, pressure transducers, encoders).

Rigsight node conditions signals and streams data (wired or wireless).

Live dashboard shows graphs, gauges, alerts, and status indicators.

Logging & reports capture runs with timestamps, limits, and notes.

Features

Real-time telemetry with low-latency updates

Configurable alerts (thresholds for pressure, load, position)

Session logging with take numbers and operator notes

CSV/JSON export for engineering analysis and compliance packs

Replay mode to compare test vs. live takes

Modular hardware for small props to large motion rigs

Ruggedised for workshop and on-set environments

Integration & Compatibility

Works with hydraulic and pneumatic systems

Supports common industrial sensors (4–20 mA, 0–10 V, strain gauge/bridge, TTL encoders)

Can interface with PLC/relay interlocks for safety inhibits

- Can interface with motion control systems

- Web browser access to high level display – Continuity and VFX

Use Cases

Lift / drop rigs: verify loads and stroke before camera.

Pneumatic effects: confirm pressure profiles and cycle timing.

Motion rigs: track position/velocity vs. cue.

Proof testing: generate datasets for engineering sign-off.

Troubleshooting: pinpoint pressure loss, binding, or over-load events.

Compliance & Documentation

Rigsight supports UK/EU machinery safety workflows by providing objective evidence for:

Risk assessments & technical files

Test certificates & inspection records

Commissioning reports with plots and limits